Smaller equipment

- Hot plate

- Vacuum hot plate

- High temperature muffle furnace

- Low temperature vacuum furnace

- Spin coater

- Climate chamber

- UV encapsulation

- Glass bottom solar box

- Sample preparation area

The E-MAT facility provides a protected argon atmosphere for the synthesis of a new generation of functional energy materials, representing one of the pillars of securing sustainable energy solutions in the future.

The facility is open to both academia and industry and consists of 15 glovebox modules that are interconnected by a transfer system and house a series of advanced materials research equipment.

The E-MAT facility provides a cross-disciplinary environment and platform for discovering and synthesizing new functional energy materials and is located at DTU, Lyngby in Greater Copenhagen.

The first of its kind in Northern Europe, the facility consists of 15 interconnected gloveboxes encompassing a cluster of key equipment within an inert atmosphere. This includes state-of-the-art deposition methods, to enable control of surfaces and interfaces at the atomic scale and ensuring safe handling of delicate materials.

As a national and international centre of excellence for education and research, the aim is to foster innovation and creativity, and open new opportunities for students and visiting researchers, across universities as well as industry.

E-MAT is run in partnership with University of Southern Denmark, University of Copenhagen, and Aarhus University. E-MAT is open to both academia and industry and aims to encourage new collaborations to evolve between universities and industrial partners.

The E-MAT facility consists of 15 glovebox modules that are interconnected by a transfer system and house a series of advanced materials research equipment in a protected argon atmosphere. The glovebox environment houses 6 advanced materials deposition systems along with smaller pieces of equipment.

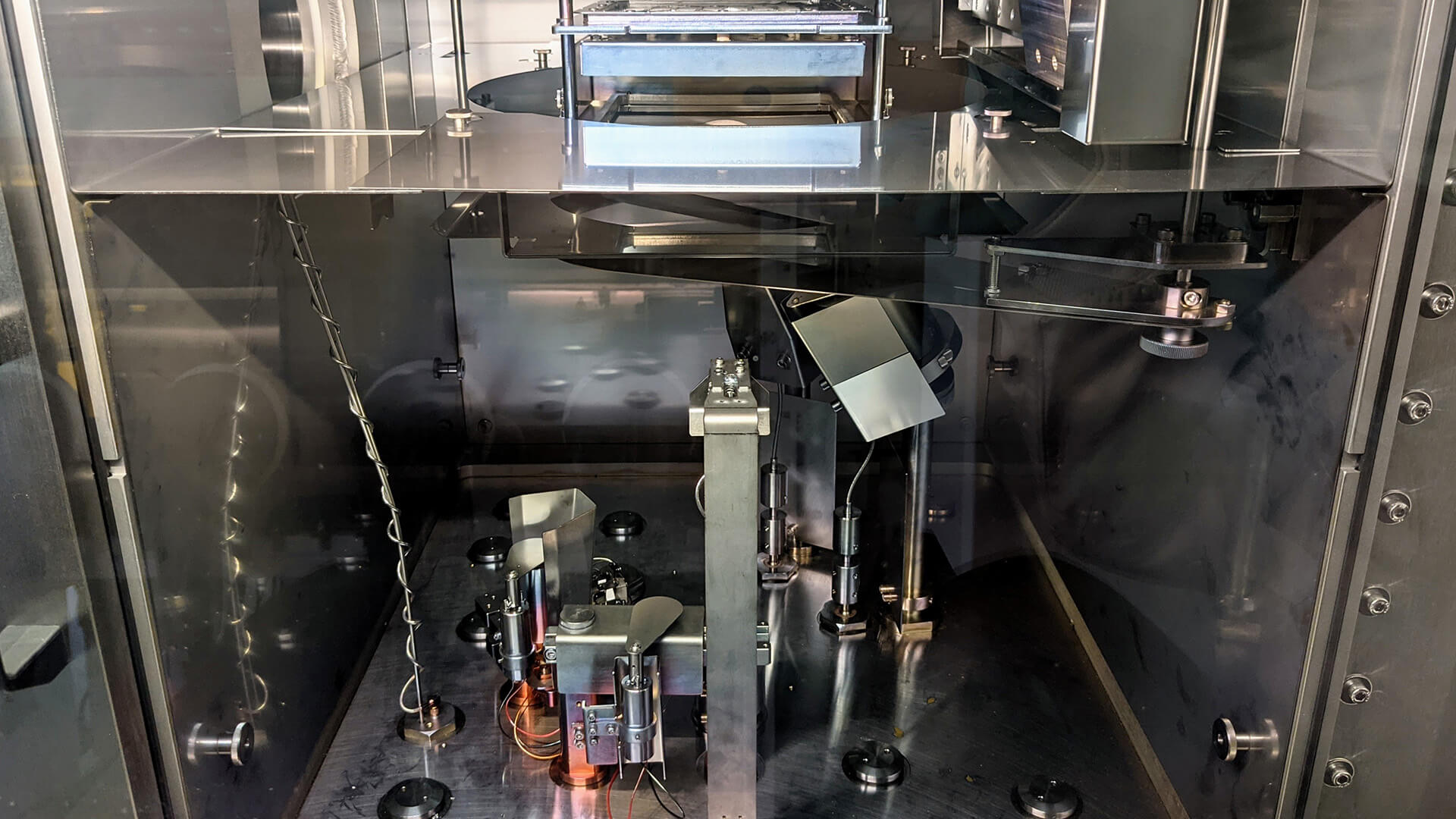

The OPTIvap physical vapour deposition (PVD) chamber from Creaphys allows both low temperature and high temperature thermal evaporation and DC, pulsed DC and RF sputtering. It also allows for reactive sputtering using oxygen and nitrogen.

The Picosun R-200 advanced ALD system is a hot-wall design with substrate temperatures in the range 50-500C and is suitable for both solid and liquid precursors.

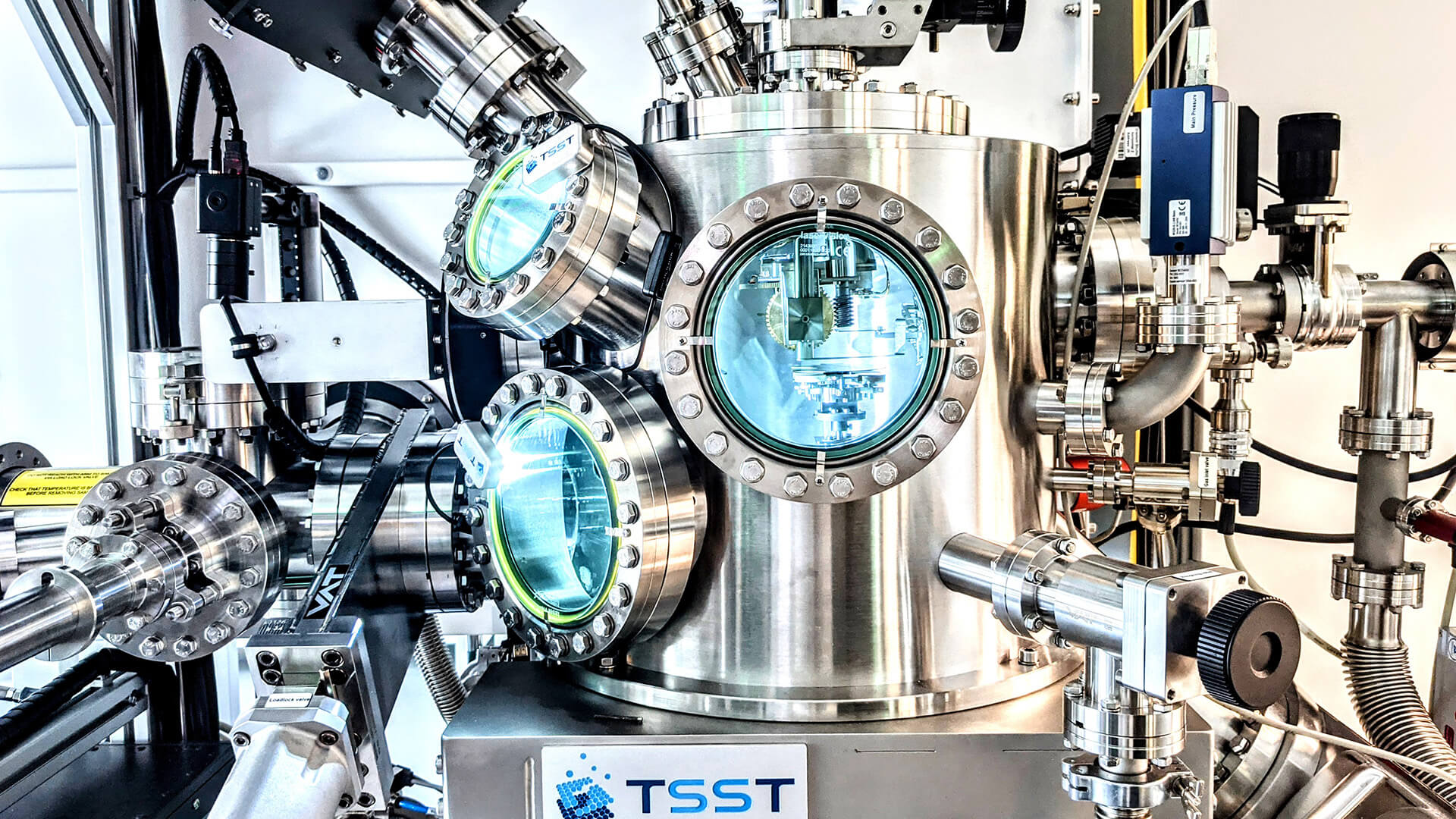

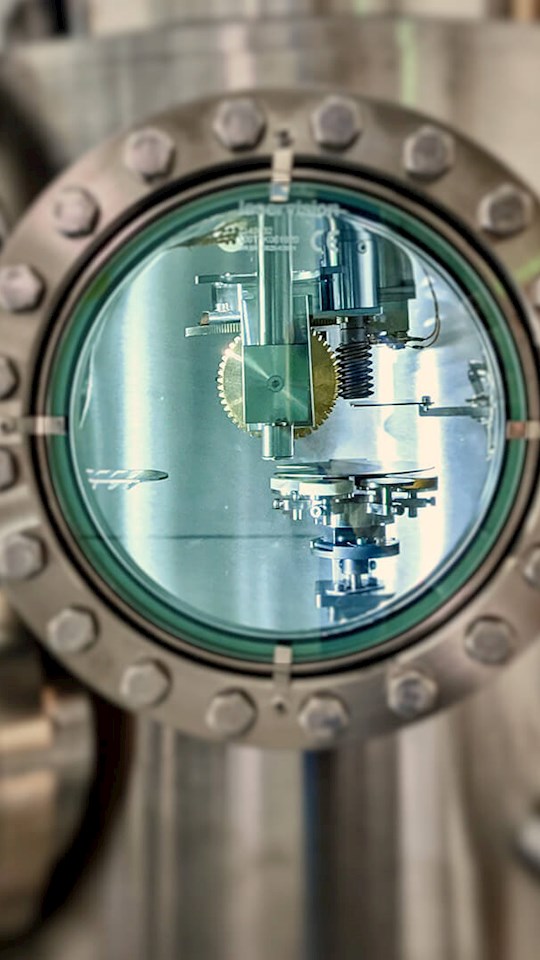

The TSST PLD is designed for the deposition of highly stoichiometric thin oxide films. It includes a KrF excimer laser (248nm), laser heating and in-situ RHEED monitoring of the growth.

The Lithoz CeraFab 2M30 uses CAD to build 3D ceramic parts, layer by layer. It has an x/y resolution of 35 μm and layer thickness in the range 10-150 μm.

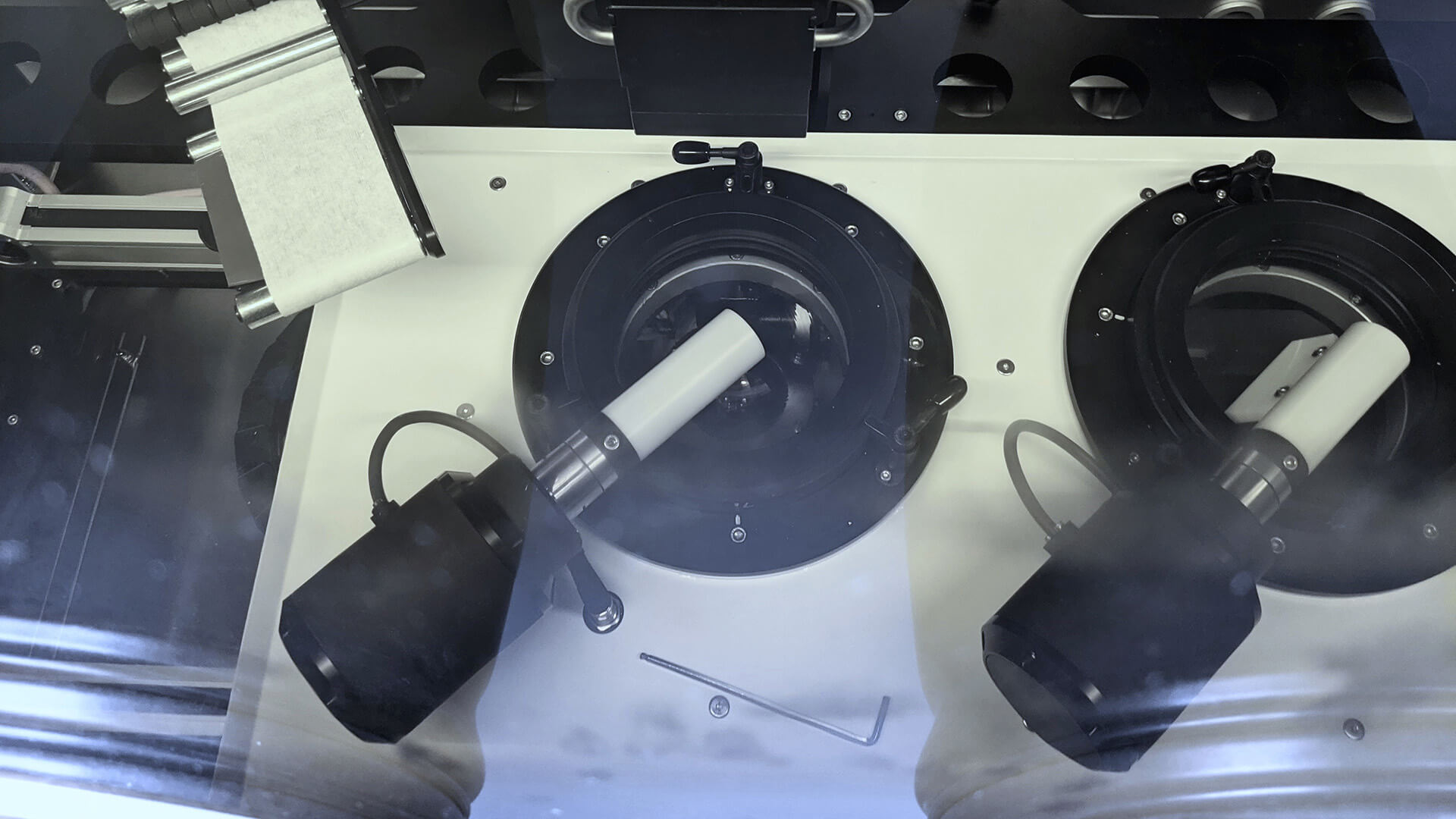

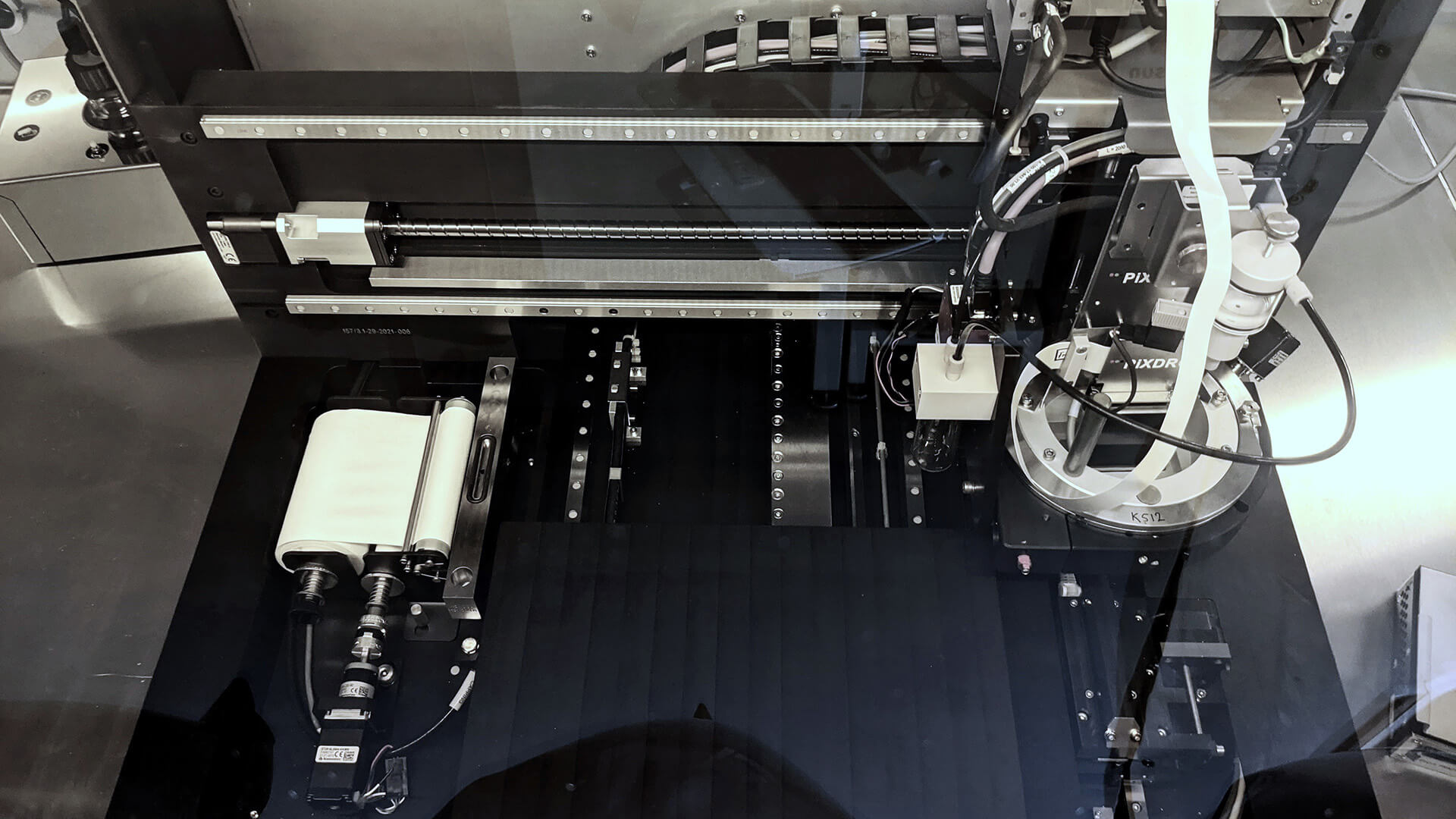

The PiXDRO LP50 R&D inkjet printer is designed for functional printing of features down to 20 μm, providing an alternative to traditional techniques such as lithography, encapsulation and adhesion.

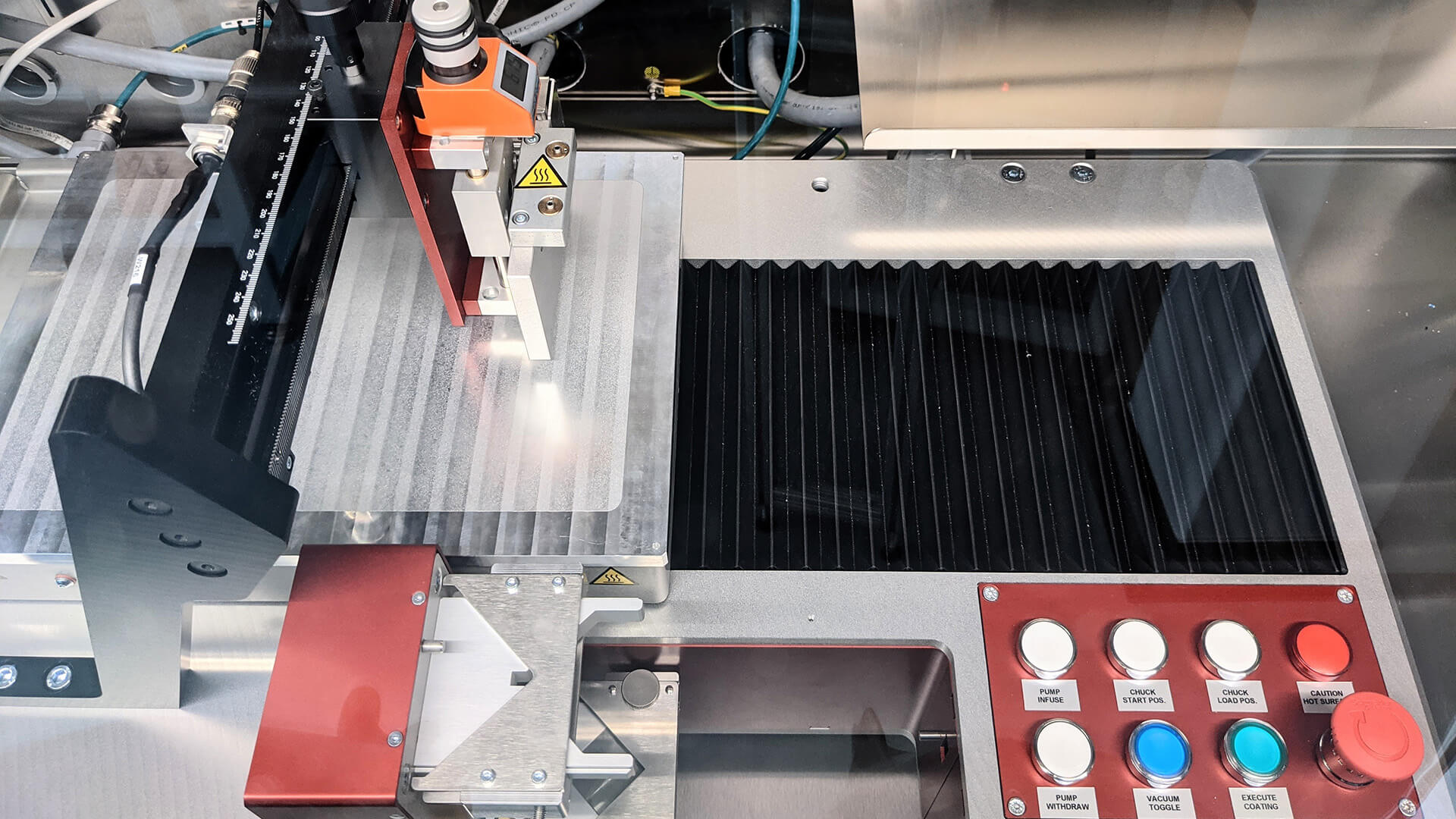

The FOM VectorSC provides controlled coating of both rigid and flexible substrates up to A4 size, with coating widths from 1mm to 200mm.

The facility is open to both academic institutions and industry. For information on how to book access to the E-MAT facility please contact us.

Research

Considered the holy grail of next-generation battery technology, in contrast with other so-called “beyond Li-ion” technologies, such as Mg-based or metal-air batteries, SSBs are around the corner, as stated by Toyota’s recent announcement of being the first SSB driven car by 2020. Solid-state batteries offer multiple advantages, such as high energy density, high power density, as well as being cheap, safe and environmentally friendly.

Research

Research and development of new types of organic, hybrid and perovskite thin-film solar cells represent some of the cutting-edge technologies driving the green transition. Metal halide perovskite solar cells have achieved low-cost fabrication and an impressive power conversion efficiency, which currently stands above 25%. Despite this there are still key challenges to overcome, which requires high quality fabrication and well controlled film stoichiometry.

Research

Catalysts made from so-called ‘high-entropy alloys’ may be the key to the renewable energy materials essential for the chemical industry as they phase out oil and gas in the years ahead. High-entropy alloys have already been shown to possess exceptional properties, exceeding those of conventional alloys, and other outstanding high-entropy alloys are likely to be discovered in the future.

The facility is supported by the research infrastructure pool of the Ministry of Higher Education and Science, with funding matched by a national collaboration between the University of Copenhagen, the University of Southern Denmark, Aarhus University, and the Technical University of Denmark, DTU.